It can control the filling volume to ensure that the same amount is filled each time, thus improving the efficiency of the production line and the quality of the product. It is commonly used in production lines for pharmaceutical, cosmetic, food and other industries.

According to the way of material dosing, quantitative filling machine is usually classified into: volume type, weight type and liquid level type.

Volume quantitative filling machines, also known as volumetric filling machines, are filling methods that distribute equal volumes of materials into containers, and are the most common fluid filling methods on the market today. There are three common ones as follows.

Volumetric filling machines are mostly suitable for liquids, pastes and powders, different material properties correspond to different types of filling machines; for example: low viscosity liquids use gravity filling machines, while viscous sauce requires the use of piston or pump filling machines.

For more information on volumetric filling machines, please click on the following articles to learn more.

A volumetric filling machine is a type of filling equipment used in packaging and processing industries for filling containers with precise volume of liquids, pastes, or other free-flowing materials. It works by measuring the volume of product dispensed into a container, rather than the weight or height within a bottle. Types of Volumetric Fillers Three popular types of volumetric filling.

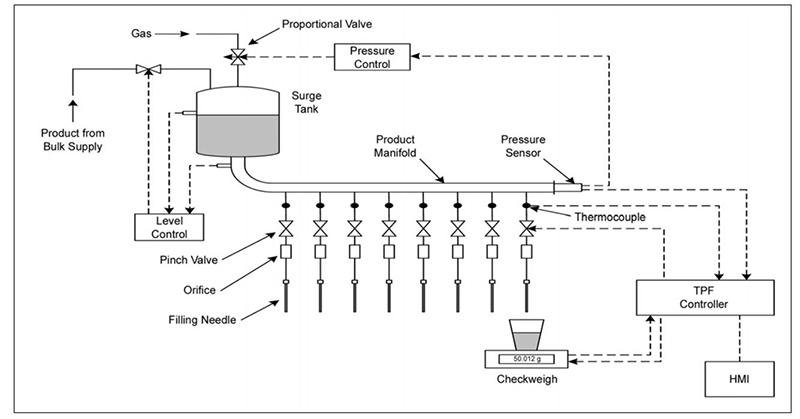

A weight-based quantitative filling machine is a filling machine that distributes an equal amount of material into a container based on weight. Usually a weighing device is installed under the container and sensors equipment to complete the filling action, the container enters the filling station, the weight counter is zeroed, the filling nozzle begins to distribute the material, and the filling stops after the specified weight is filled.

Weighing type quantitative filling machine can be used for liquid, paste, powder as well as solid granulars. Of course granular weighing common with multi-head scale packaging machine (solid quantitative packaging is not in the scope of this article).

The liquid level quantitative filling machine is not strictly speaking a filling method of completely equal distribution, it is based on the height of the liquid in the container to determine the filling volume. Usually when the container goes into the filling station, the filling nozzle starts to dispense liquid until the fixed container position and then stops filling. Overflow filling machine is one of the common liquid level filling machines. The overflow filling nozzle is equipped with a unique suck-back function, which can suck back the liquid and foaming above the liquid level to the designated container.

Liquid level quantitative filling machine is only suitable for liquid with good fluidity, common white wine, white vinegar vinegar, etc. Recommend to use overflow filling machine. Click the following article to know more information about overflow filling machine.

The overflow filling principle stands out for its ability to fill bottles to the same level, even if that results in slight variations in volume. For retail products packaged in clear containers, this visually-appealing evenness is an important way to appeal to your customers. Without this system, slight variations in the interior shape of your containers could make it look.

When you buy a quantitative filling machine, you need to consider the following main factors:

Material characteristics determine which machine to choose, usually need to know the viscosity of the material, whether the filling process foaming, corrosive (generally filling equipment is made of stainless steel).

Viscosity determines which type of machine should be used: gravity filler and overflow filler suitable for filling liquid with high liquidity, such as water, white vinegar, etc.; piston filler and rotor pump filler suitable for filling slightly higher viscosity liquids and pastes, such as: sauces, edible oils, lubricants, cosmetics, etc.; peristaltic pump filler suitable for filling many categories and filling small amounts of liquid, such as eye drops, nail polish, etc.

Common liquid packaging containers are: bottles, jars, cans, tubes, bags, barrels, etc.; different containers have different filling machine options; bottles and jars below 5 liters, piston, gravity overflow fillers are good choices, more than 5 liters are mostly used weighing filler; tubes generally use tube filling and sealing machine, bags also have special bag filling machine.

In addition, the shape of the container will also affect the configuration of the filling machine, whether it can run on the conveyor belt, etc.

Each type of filling equipment is available from manual, semi-automatic to fully automatic machines can be selected.

Capacity determines the degree of automation of the machine, usually a few hundred to a few thousand per day, semi-automatic or manual equipment can be completed, when you need to package tens of thousands of bottles per day when the automated equipment will be a better choice. Production capacity depends on the packer's current sales and the prediction of future sales.

These are the most important and basic factors to consider when buying a quantitative filling machine, but of course you also have to consider the size of the site, related equipment (capping machines, labeling machines, etc.), cleaning and maintenance of equipment, manufacturer's after-sales installation, etc.

VKPAK is a professional manufacturer of liquid filling equipment, if you are looking for quantitative filling machine, please contact our professional team, we will provide you with professional and thoughtful advice and reliable quality machines and equipment .